Encoder Applications/Logistics Industry

Encoder for Logistics Inductries

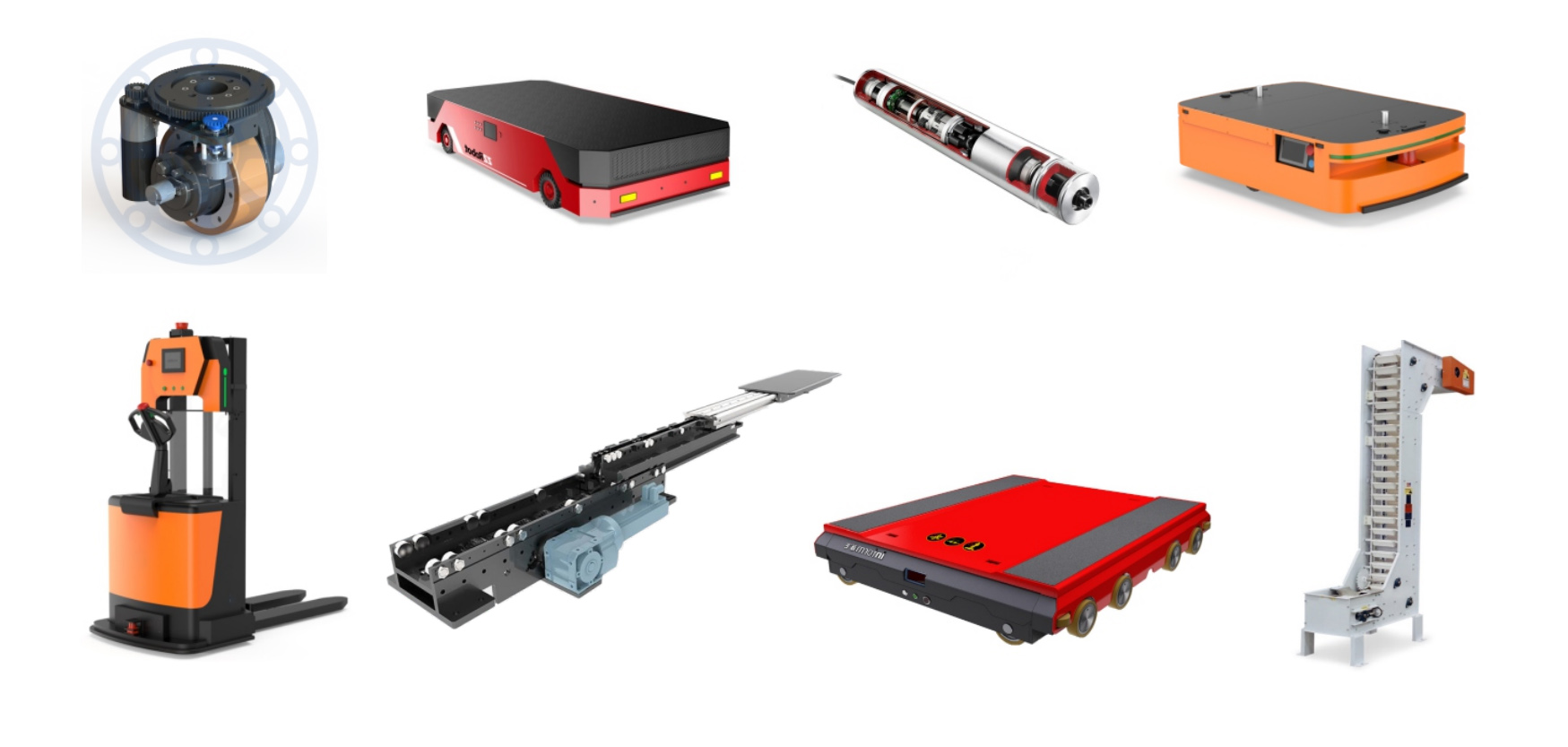

With the development of automation and unmanned driving technology, various automated logistics equipment has been widely used in the logistics industry; Adike encoders are various automated logistics equipment, such as: unmanned forklifts, hoists, telescopic forks, rollers Motors, steering wheels, shuttle cars, AGV trolleys, heavy-duty AGVs and other equipment provide speed monitoring, corner monitoring, distance monitoring and other solutions to ensure the safe, rapid and accurate operation of various automation equipment, thereby completing the various orders issued by the system Task instructions.

Encoders in Logistics Industries:

1.Multi-turn absolute encoder;

2.Solid Shaft Incremental Encoder;

3.Through Hollow Shaft Incremental Encoder;

4.Draw Wire Encoder;

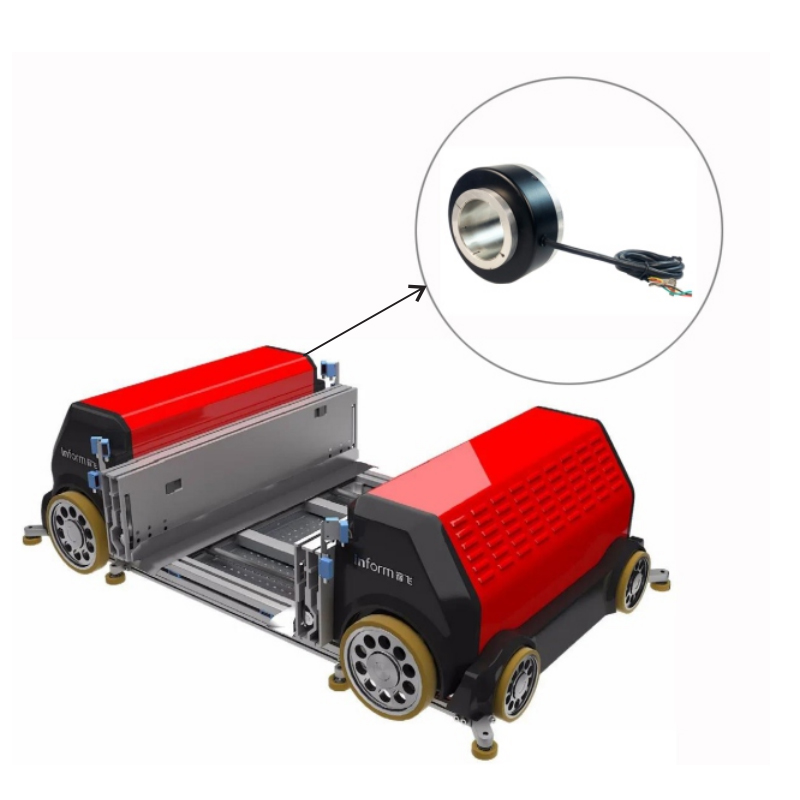

Application of encoder on AGV and steering wheel Purpose

Measure the driving speed of AGV vehicle and the steering angle when turning;

Measure the steering angle of the steering wheel; Advantages: small size, high precision, good stability, and cost-effective. Encoder selection: multi-turn absolute encoder; Optional communication protocol: CANopen.Modbus, Profibus, Profinet,EtherCAT, DeviceNet, SSI

Recommended model: GSA-38L6 Series

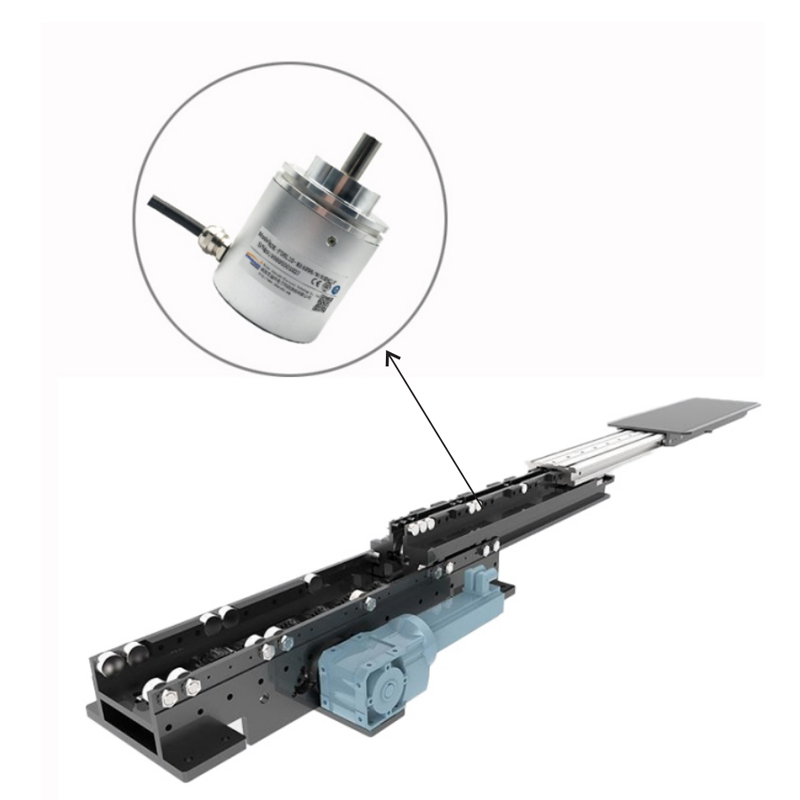

Application of encoder in telescopic forklift Purpose

Measure the traveling speed, real-time position, and steering angle of the telescopic forklift; Advantages: anti-interference and calibratable; Encoder selection: multi-turn absolute encoder;

Optional communication protocol: CANopen.Modbus, Profibus, Profinet, EtherCAT, DeviceNet, SSI, Parallel

Recommended model: GMA-F58B10-1213-B4PNLP

Application of encoder in heavy-duty AGV vehicle

Purpose: Measure the driving speed, real-time position, and steering angle of a heavy-duty AGV; Advantages: compact structure, high precision, anti-interference, and high transmission rate; Encoder selection: multi-turn absolute encoder, pull-wire encoder;

Optional communication protocol: CANopen.Modbus, Profibus, Profinet, EtherCAT, DeviceNet, SSI, parallel

Recommended model:

GMA-F58L10 series, GI-D20 series, GMA-F58B10 series

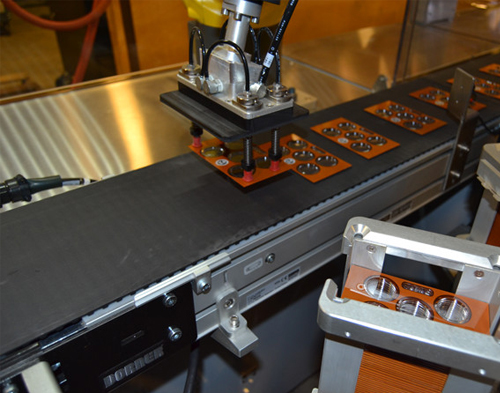

Application of encoder in shuttle car

Purpose: measuring the speed of the shuttle car and the steering angle when turning; Encoder selection: large hollow incremental encoder;

Optional output mode: NPN open collector, PNP open collector, push-pull output, differential output, voltage output

Encoder selection recommendation

Recommended model: GHI-80 series

Application of encoder on hoist machine

Purpose: measure the position of the hoist; Advantages: sturdiness, high reliability, long life, strong environment resistance; Encoder selection: hollow incremental encoder;

Optional output mode: NPN open collector, PNP open collector, push-pull output, differential output, voltage output

Recommended model: GHI-60 series

Application of encoder in unmanned forklift

Purpose: Measure the lifting height of unmanned forklifts; Advantages: precision, stability, compact size;

Encoder selection:

Pull wire encoder; Optional measuring length: 500mm-10000mm; Optional output mode: NPN open collector, PNP open collector, push-pull output, differential output, voltage output

Absolute encoder: CANopen.Modbus, Profibus, Profinet,, EtherCAT, DeviceNet, SSI, etc. Analog output: 4-20mA, 0-10v

Encoder selection recommendation Recommended model: ADK60 series